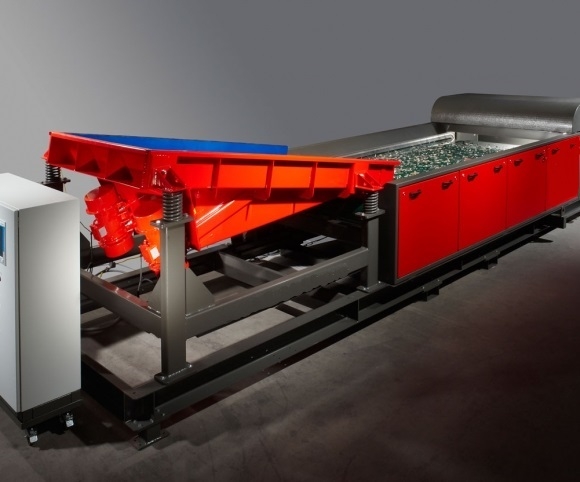

Metal Detectors I-Sens conveyor belt continuous

A recent development is the I-Sens sensor separator. This system perfectly complements the separation process before or after the eddy current separators! The separation principle consists of a conveyor belt in which a sensor plate is mounted just before the final roller. This sensor plate detects a metal particle as well as the line along which this metal particle is located on the belt. Then the software calculates the exact location, and the metal particle is then ejected from the steam with an air pulse during its free-fall curve after which it falls behind a partition.

Several advantages of the I-Sens sensor separator:

- adjustable sensor sensitivity

- suitable for all types of metal

- product quality improver

| Suitable for belt width | 400 – 2000 mm |

| Removes | All metals (iron, non-ferrous, stainless steel) from 5 mm |

| Cleaning | Automatic and continuous, without process interruption |

| Application | Used for final inspection to ensure that the final product no longer contains any metal. |

| Applications | Household waste (shredded), incineration slags from household waste, W.E.E.E. scrap, glass recycling, heavy and light shredder residues (e.g. auto shredder residue), wood and/or chipboard recycling, product or waste flows that require quality improvement, separation of stainless steel |

| Max. layer thickness | Mono-layer, as open as possible |

Available standard articles:

- No standard articles available; configuration is composed client specific.